Temporary Water Treatment Made Easy with Aria FAST

Temporary Water Treatment Made Easy with Aria FAST

January 10, 2025

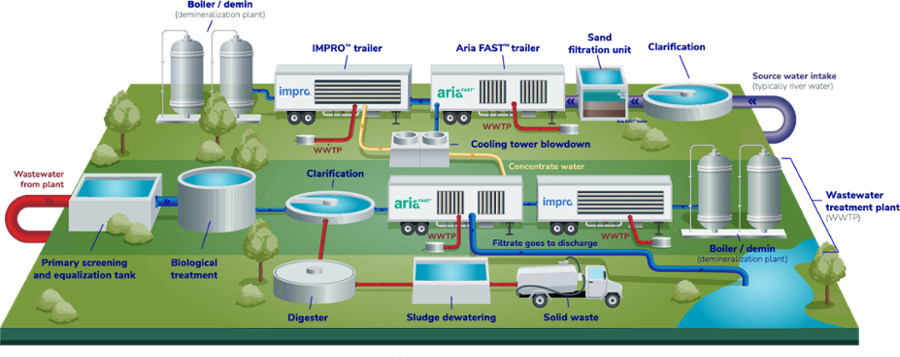

The need for a temporary water treatment solution is common for a range of industrial businesses, including petrochemical processing, mining, food and beverage, and more. Such solutions may be needed to address seasonal changes in water composition, to temporarily add capacity, to help stay within discharge permit limits, or as a bridge solution for a permanent installation. Regardless of the reason, a temporary treatment solution needs to be able to remove necessary contaminants to produce the required water quality at the volumes needed for the application.

With this in mind, Aria Filtra – a division of Trojan Technologies – developed the Aria FAST system. This mobile, modular water treatment system can be deployed quickly to help protect capital equipment and ensure regulatory compliance. The system is highly automated and features remote monitoring capabilities, allowing it to operate effectively with minimal on-site intervention.

Making the Most of Membranes

Formerly known as Pall Water, Aria Filtra is a leader in membrane technology applications. As such, Aria FAST relies on microfiltration (MF), ultrafiltration (UF), and reverse osmosis (RO) to provide high-quality mobile water treatment. Membranes use a mechanical barrier to remove particles by forcing the water under pressure through pores too small for target molecules. Membranes are an ideal solution for many temporary industrial water treatment applications because they are a dead-end technology –– in other words, the water is able to pass through, but nearly all other contaminants are rejected. Unlike sand filters, membranes can remove large amounts of total suspended solids (TSS) without slippage or breakthrough. In addition, ion exchange (IX) and granular activated carbon (GAC) are only effective against a limited range of contaminants, whereas membranes can reject anything larger than the pore size. The ability to backwash membranes, as well as perform clean-in-place, ensures that operators do not have to spend time changing out filters during the contract period.

Of course, not all applications are right for membranes. For example, water temperatures above 104°F can damage the media. Similarly, if the plant only needs to reduce water hardness, then IX filters may be more effective. In addition, water with high levels of iron, manganese, or total organic content (TOC) may require prefiltration to avoid clogging or fouling membranes.

Maximizing Recovery, Minimizing Costs

One thing that allows Aria FAST to stand out among other temporary water treatment solutions is its IMPRO closed-circuit reverse osmosis (CCRO) technology. Typical RO systems produce about 50% permeate. Achieving higher recovery usually requires two or three stages of filtration, which increases costs significantly.

Rather than use a second series of membranes, CCRO continuously recirculates concentrate back to the beginning of the system, blending it with new feed water. This cycling continues until the system reaches an established saturation point for a controlling element. Overall, the process is able to recover as much as 90% of reject. The single-stage process reduces pressure requirements, leading to lower energy costs compared to multi-stage high-recovery RO.

Automated Monitoring and Remote Control

Aria FAST is equipped with advanced features to make it an efficient and user-friendly solution for any industrial application. Each trailer comes with a PC and HMI screen, as well as numerous sensors and analyzers. The system can connect to the plant’s own SCADA or other monitoring system via Ethernet, wireless, or satellite, depending on the specific infrastructure and security protocols. Using the Aria SMARTBOX remote logging platform, operators can keep tabs on the system from anywhere, as well as run reports, receive alerts, and more.

At the same time, Aria Filtra staff can engage in proactive remote monitoring through the eGuardian service. This allows operators to focus on other priorities. If an issue comes up, Aria Filtra staff can alert the customer.

Unlike other temporary water treatment solutions, Aria FAST is otherwise largely automated, requiring only one or two check-ins by operators during a given shift. Backwashes, CIP, and other processes are engaged on a schedule without manual intervention. If a rare event requires a membrane to be changed or a housing to be adjusted and the customer’s team does not have the necessary experience or skills, Aria Filtra can send its own personnel to the site to handle the task.

Fill out the form to get in contact with an expert who can answer any questions you may have about the Aria FAST mobile systems.

Contact Us